It has been more than two months since my last post. Sorry about that, I don’t expect that to be the norm but I’ll explain the reason for the break later in the post.

First off, I want to start this post by walking through the transom work.

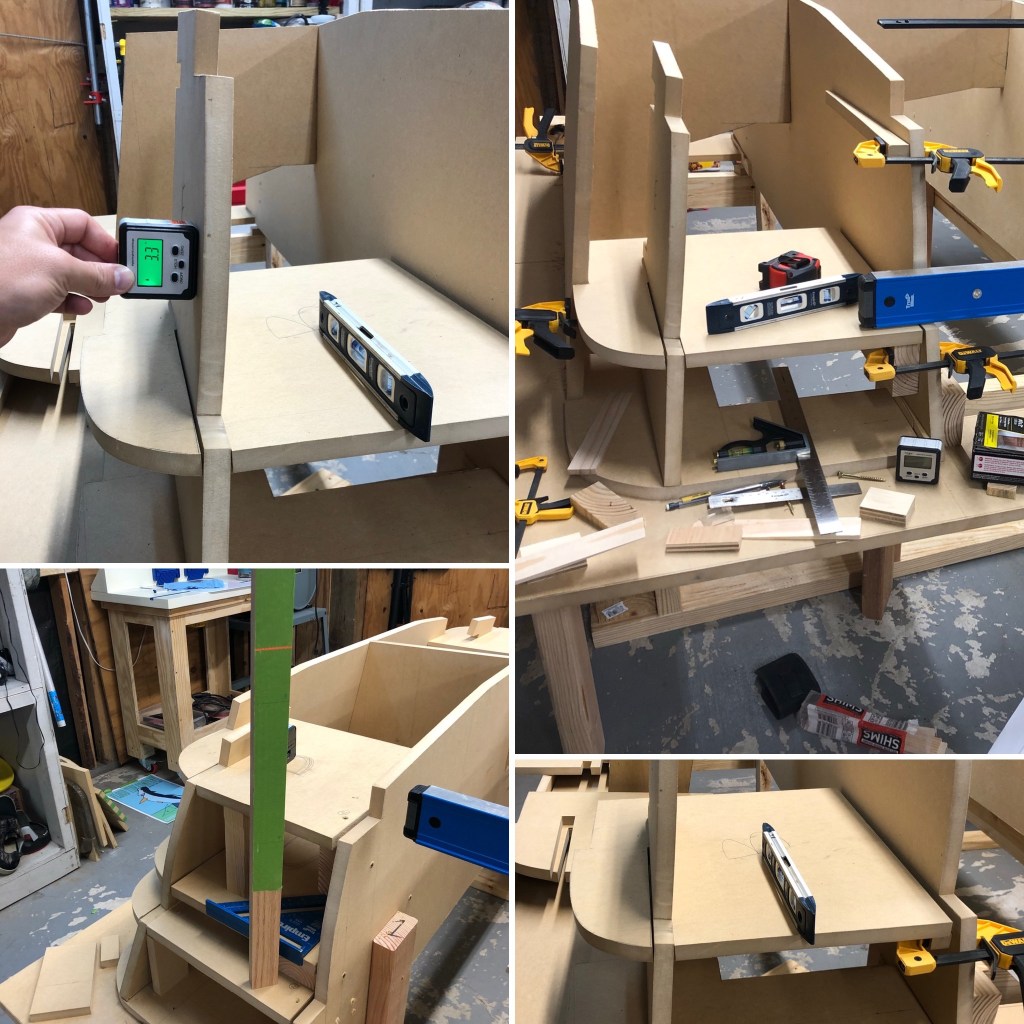

As you can see in the pictures above I did a lot to check for level and parallel. Going back to the laser trick from the earlier post. I made sure that the starboard and port sides were at the same elevation as one another.

I was all finished with the forms for the hull around the beginning of December and was hoping to make some major progress over the holidays.

The next step is putting structural foam on the forms. Lesson Learned to those that follow, the good foam is made in Europe and can take a while to procure if your supplier does not have any in stock. Due to all the Covid craziness, the warehouse in Florida was out of stock. Because of the $/sheet, I was willing to wait.

I ordered 15 sheets of Divinycell H80 from Merritt Supply. I don’t think I will need 15 sheets but that is how many come in a box and there was a HUGE discount for buying a box versus buying it by the sheet. Total cost for 15 (4’x8’) sheets, plus shipping from Pompano Beach, FL to Clear Lake Shores, Texas, was $2,474. I worked hard to source that and it was by far the cheapest I could find.

I placed my order December 11 and I was ready for it the day I ordered. I was quoted 3 weeks originally so with all my time off I decided to give the shop an overhaul.

Anyways, the foam is supposed to arrive tomorrow and I could not be more excited. Crossing my fingers there are no issues and I can hit the ground running!

For every minute spent in organization, an hour is earned.

Benjamin Franklin

Outstanding work! Way to keep the project a float………

LikeLike

Excellent pun sir!

LikeLike